As part of the Artemis program, NASA is returning astronauts to the Moon, where they will prepare for human exploration of Mars. Additive manufacturing, or 3-D printing, experts from NASA, industry, and academia are pioneering methods to print the rocket parts that could power those journeys.

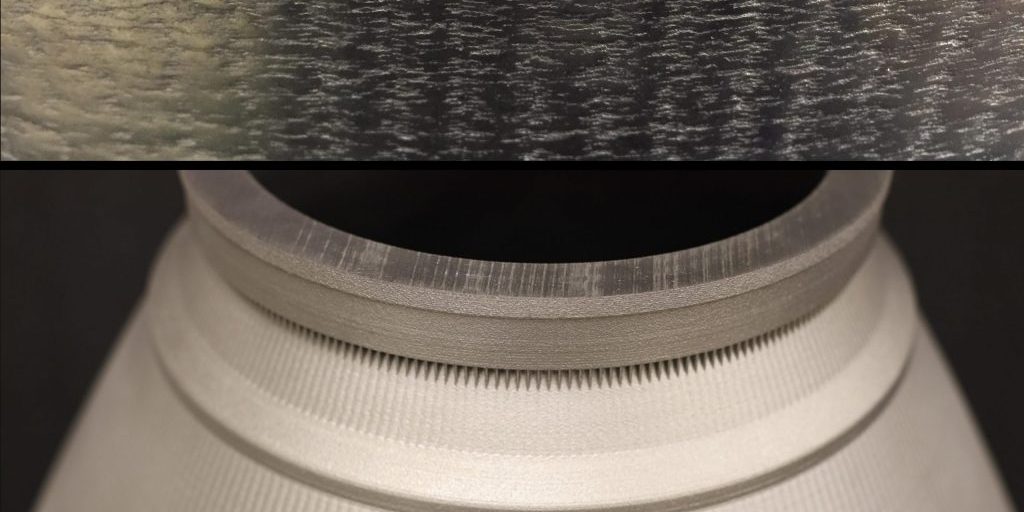

NASA’s Rapid Analysis and Manufacturing Propulsion Technology project, or RAMPT, is advancing development of an additive manufacturing technique to 3-D print rocket engine parts using metal powder and lasers. The method, called blown powder directed energy deposition, could bring down costs and lead times for producing large, complex engine components like nozzles and combustion chambers. Prior developments in additive manufacturing did not have the large-scale capabilities this emerging technology provides.

“This technology advancement is significant, as it allows us to produce the most difficult and expensive rocket engine parts for a lower price tag than in the past,” said Drew Hope, manager of NASA’s Game Changing Development Program, which funds the RAMPT project. “Further, it will allow companies within and outside of the aerospace industry to do the same and apply this manufacturing technology to the medical, transportation, and infrastructure industries.”