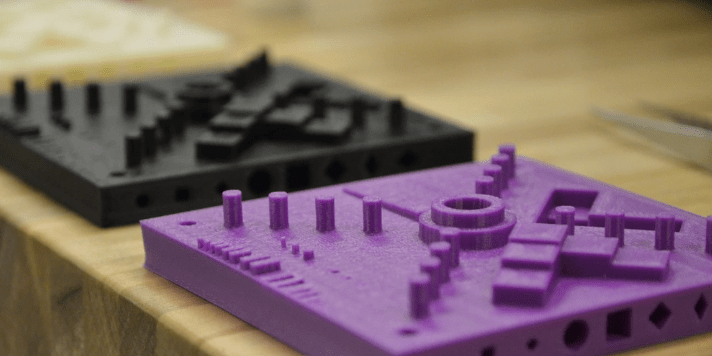

Additive manufacturing (AM) of plastic and metallic components offers a way to revolutionize and improve the military supply chain by providing the ability to build at the point of use, as components are demanded, and addressing components no longer manufactured or supported for legacy weapons systems. However, AM processing parameters are difficult to tune and greatly impact the printed structure, microstructure, and performance of the subsequent products, resulting in much variability in component-level product quality. It is difficult to build process-structure-property-performance relationships for AM using traditional numerical and analytical models due to the large number of potential material systems and required uses. Monitoring AM processes and measuring AM materials and parts have become commonplace and increasingly precise. As larger volumes of data on AM parts become available, machine learning (ML) can be deployed to gain insight into the fundamental physics behind AM processes and identify predictive and actionable paths forward to optimize part quality and process design.

In this webinar, we give an overview about the different pieces of an AM component’s manufacturing life cycle (from feedstock to final use) and discuss the advantages of using ML on AM for quality control, including hurdles that limit its present range of applications. Existing capabilities and future trends are discussed that will allow military engineers to better deploy this technology in future conflicts with near-peer adversaries.

Specifically, this webinar will cover the following topic areas:

- Introduction to AM areas for AI/ML – Design, Process, and Materials; Qualification and Certification; Nondestructive Evaluation; and Maintenance

- AI and ML Methods

- Materials State Factors

- AM Areas of Interest for Implementing AI/ML Models

- Roadmaps by DoD, Other Governments, and Industry

- Government Integration of AM and AI/ML