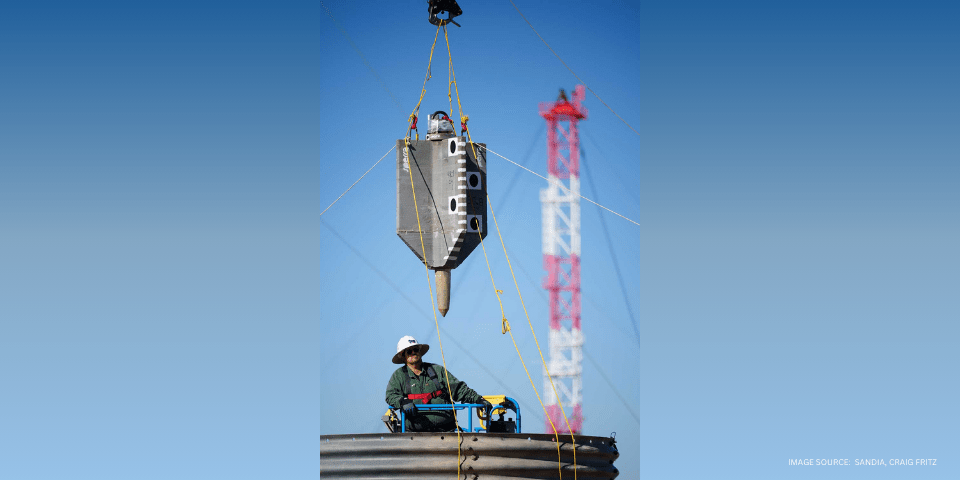

Beside a 50-foot-deep pool, a 300-foot metal tower rises into the air at Sandia New Mexico. Cables and a vertical guided trolley attached to the tower allow personnel to hoist objects to varying heights so they can watch them fall at Sandia’s Drop Tower and Water Impact test facility. Built in late ’50s and early ’60s, the site has been used for impact testing on containers that transport hazardous materials, weapons testing and underwater impact testing. Last month, the facility dropped anchor — torpedo anchors.

Torpedo anchors, heavy arrow-shaped weights, are completely embedded in the seafloor. Traditionally made of steel or other metals, the anchors are fiscally and environmentally expensive. Sperra, a clean-tech company specializing in automated construction for marine energy, is seeking to lower both of those costs by developing anchors that meet performance requirements but also minimize environmental impact.