INTRODUCTION

The 5,000-lb class BLU-113 “Bunker Buster” bomb was designed to hit multilayered, hardened underground targets during Operation Desert Storm. During testing, the weapon was shown to penetrate more than 100 ft of earth and 20 ft of solid concrete. Recognizing the need to penetrate not only concrete but also rock, however, the Air Force in 2003 directed the development of the BLU-122 to enable greater hard-target penetration. Unfortunately, while the BLU-122 incorporates more energetic explosive fill, higher-strength case material, and a modified nose shape, it possesses only 18–20 ft of penetrability in 5,000-psi-strength reinforced concrete.

This article briefly highlights a cost-effective new case design for the BLU-122 that incorporates a new high-strength steel (or M-steel) and demonstrates a >50% projected increase in penetrability in 5,000-psi-strength reinforced concrete compared to the standard case, which uses the well-known Eglin steel (or ES-1) [1].

MATERIAL AND COST COMPARISON

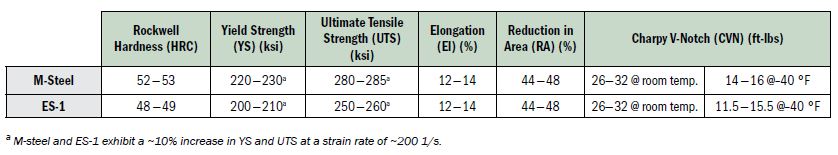

Table 1 provides a comparison of quasi-static tensile test results at room temperature, as well as of Charpy v-notch (CVN) test results at room temperature and at -40 °F, for the air-melted quenched and tempered M-steel and ES-1 [2]. As shown, M-steel is stronger than ES-1 (as evidenced by the yield strength [YS] and ultimate tensile strength [UTS] values) while having the same level of ductility and toughness (as evidenced by the elongation [El], reduction area [RA], and CVN values) [3]. In addition, M-steel has a reduction in raw material cost of 50%or more compared to the ES-1, while the cost of manufacturing, including melting, forging, machining, and heat treatment of the two cases is similar. This steel also possesses better formability at hot forging and better machinability at rough machining of cases.

Table 1: Comparison of Tensile and CVN Test Results for M-Steel and ES-1 (Source: Advanced Materials Development Corporation).

PENETRATION PARAMETERS AND CALCULATIONS

One reason a bomb’s material is so important is that the nose of the penetrator plays a crucial role in its strength and durability. If a penetrator material does not have enough strength, large deformation of the nose and wall can occur. As a result, the nose can be flattened and the wall can be warped. On the other hand, if a material (even a high-strength material) does not have enough impact toughness, a fracture of the nose and wall can occur. Both scenarios can lead to a reduction of penetration distance and a failure to meet the strict requirements for the penetrators.

The main parameters that affect penetration distance are:

- Strength and toughness of the case material

- Shape and length of the nose

- Length of the penetrator

- Thickness of the wall

- Diameter of the case

The penetration distance of the penetrator for the proposed new case design was calculated using equation 3.2 of Young’s “Penetration Equations” for soil, rock, and concrete targets [4]. In addition, the penetrability of the conic nose and tangent ogive nose shapes (N-factor) was calculated using equations 3.7 and 3.9, and the penetrability of target (S-factor) was calculated using equation 4.2 of the same source.

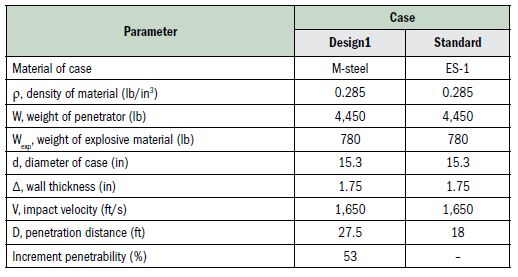

Table 2 shows a comparison of penetrability of a new designed case (Design1) with M-steel and the standard BLU-122 with ES-1. Note the cases have the same material density, penetrator weight, explosive material weight, case diameter, wall thickness, and impact velocity. This velocity corresponds to dropping the projectile from a height of 41,500 ft with negligible air drag.

Table 2: Penetrability Comparison of Design1 and Standard Cases (Source: Advanced Materials Development Corporation).

The calculation of the S-factor for concrete assumes that a target is 5,000-psi-strength reinforced concrete with the following properties: volumetric % rebar, P = 2; cure time, tc = 1; thickness of the target, in penetrator diameters, Tc = 6; unconfined compressive strength, fc = 5,000 psi; target width, in penetrator diameter, WID > 20, and Ke = 1. In addition, calculation of the N-factors for both cases assumes that both cases have modified nose shapes.

As shown by the calculated penetration distances in Table 2, the penetration of the BLU-122 with the standard case in 5,000-psi strength reinforced concrete is ~18 ft, which closely approximates the actual test data [5]. The new case with the M-steel has a projected penetration of ~27 ft, which is an increase of more than 50%.

SUMMARY

With a >50% increased penetrability in reinforced concrete, a 50% or more reduction in raw material cost, and a comparable manufacturing cost, the new M-steel bomb design offers a promising enhancement to the standard ES-1 BLU-122 design. This design change allows for the penetration of targets currently unreachable by the BLU-122 and may prove to be crucial in continued defense efforts.