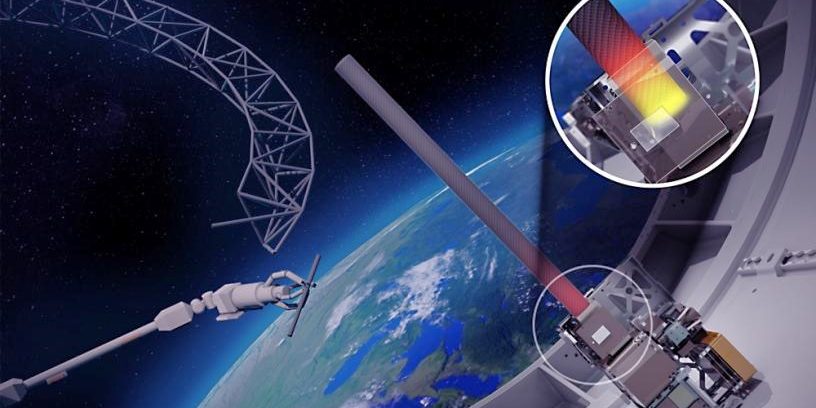

Based on outstanding technical progress by research teams to date, DARPA has pivoted the third and final phase of its NOM4D (pronounced nō- mad) program from planned further laboratory testing to conducting a pair of small-scale orbital demonstrations to evaluate novel materials and assembly processes in space.

As commercial space companies continue to expand access to orbit for U.S. economic and national security needs, a major roadblock for building large-scale structures in orbit remains: the size and weight limits imposed by a rocket’s cargo fairing. In 2022, DARPA introduced NOM4D to break this cargo-constraint mold by exploring a new paradigm. Instead of folding or compacting structures to fit them into a rocket fairing to be unfurled or deployed in space, DARPA proposed stowing novel lightweight raw materials in the rocket fairing that don’t need to be hardened for launch. The intent of this approach is to allow in-orbit construction of vastly larger and more mass-efficient structures than could ever fit in a rocket fairing. Additionally, this concept enables mass-efficient designs of structures that would sag under their own weight on Earth but are optimized for the low-gravity environment of space.