Introduction

For many years, the U.S. Navy has held a distinct technological advantage over its adversaries in the area of large conventional guns that use explosive energetic propellants to fire projectiles (e.g., those found on U.S. cruisers and destroyers). Over the last few decades, that advantage has been in a steady state of decline as the amount of permissive operating space has become more contested. New advanced weapon systems have long been promised as solutions intended to reverse this trend. Accordingly, advanced weapons systems such as railguns offer greatly increased range, firing rate, and lethality while also promising substantial improvements in storage and handling safety. However, the transition of such advanced weapon systems from the laboratory to the theater has become quite precarious as decision-makers have struggled with the challenges of competing research and development (R&D) priorities. Recently, with a renewed desire to ease such impasses, national leaders are displaying greater optimism with regard to the outlook for advanced weapon systems development.

In November of 2014, then U.S. Secretary of Defense, Chuck Hagel, released a memorandum for the Defense Innovation Initiative (DII). In the memorandum, Secretary Hagel stated that “We are entering an era where American dominance in key warfighting domains is eroding, and we must find new and creative ways to sustain, and in some areas expand, our advantage even as we deal with more limited resources.” He concluded the memorandum with “America’s continued strategic dominance will rely on innovation and adaptability across our defense enterprise” [1].

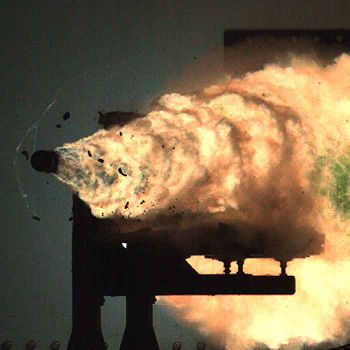

One such program with the potential to accomplish this imperative is the Electromagnetic Railgun (EMRG) Program. The Office of Naval Research (ONR) has contracted with BAE Systems and General Atomics to develop a next-generation weapon system (such as that shown in Figure 1), which aims to perform as a long-range weapon with rapid response capabilities, while also being more efficient and safer than current gun and even certain missile systems.

Figure 1: EMRG Firing at the Naval Surface.

How Railguns Work

Railguns operate by using energy stored in a bank of capacitors to send a large electric current through two conducting parallel rails and a sliding armature. This current creates a magnetic field and interacts with the current flowing through the armature, generating a force called the Lorentz force, which accelerates the armature through the barrel. The projectile, encased in a sabot (pronounced sa-‘bo), is pushed by the armature and leaves the barrel at speeds around Mach 7 [2]. Once the projectile leaves the barrel, it separates from the sabot and armature and continues towards its target. The process is illustrated in the cut-away diagram and firing process of Figure 2.

![Figure 2: Railgun Cut-Away Diagram and Firing Process [2]. Figure 2: Railgun Cut-Away Diagram and Firing Process [2].](/wp-content/uploads/2019/11/Railgun-figure-2.jpg)

Figure 2: Railgun Cut-Away Diagram and Firing Process [2].

Logistical Advantages of Railguns

Contemporary U.S. warships are armed with guns and missiles that require a chemical energy propulsion system. These chemically propelled weapons are expensive to manufacture and can provide numerous logistical challenges. Further, warships have limited storage capacity and are difficult to restock at sea; most often they must return to a depot for resupply.

Additionally, because of the explosive nature of the energetic materials required to propel such weapons, special safety measures are required for handling. Chemically propelled weapons also carry with them a hefty price tag. And, in this age of increasingly tight budgets and threats of sequestration, such legacy systems may not be the best long-term solution.

Alternatively, railgun ammunition has absolutely no chemical propellant. Instead, the projectile is launched by making use of the previously mentioned Lorentz force, which is generated by sending large amounts of current through the rail. This approach allows for the projectiles to be handled much more safely because there is no explosive propellant to be concerned with. And since railgun projectiles have no chemically propulsive elements, they can be stored without extensive munitions safety procedures and without logistical issues associated with managing projectiles. Such projectiles can be more easily transported out to sea to restock remotely located warships. Furthermore, in the same amount of space that a few hundred chemical projectiles require, thousands of railgun projectiles can be stored [3].

Precision Strike Capability

Railgun systems can launch projectiles on ballistic paths to precisely strike their targets in the range of 100 to 200 nautical miles. Such projectiles can reach altitudes around 500,000 ft before using global positioning system (GPS) technology to operate their navigational control and zero in on the target. This precision targeting is all accomplished in a time of flight to target of approximately 6 minutes [4].

Railgun strikes can also be called in by ground troops requesting support, as illustrated in the notional concept of operations (CONOPS) in Figure 3. Weapons that use chemical propulsion tend to have a large area of overpressure and fragment spray when hitting a target, which can sometimes lead to collateral damage. Railgun-launched projectiles will reach their targets around Mach 5. And since there are no explosives in railgun projectiles, the fragment pattern on impact is much more focused, allowing for much greater precision with a decrease in collateral damage [4]. An air burst variant of a railgun projectile is also a possibility for certain area effect scenarios. With this type projectile, fragments would effect the surrounding target area, which could be useful when engaging personnel or lightly armored targets.

![Figure 3: CONOPS for Railgun Scenario (NAVSEA) [5]. Figure 3: CONOPS for Railgun Scenario (NAVSEA) [5].](/wp-content/uploads/2019/11/Railgun-figure-3.jpg)

Figure 3: CONOPS for Railgun Scenario (NAVSEA) [5].

Technological Challenges

Not surprisingly, railgun development has had to overcome numerous challenges for the technology to be considered a plausible next-generation system. One challenge in particular has been the ability of the barrel to withstand multiple firings. The intense electric current and heat generated during a firing creates a harsh environment for the barrel (a prototype of which is shown in Figure 4). Currently, barrels only have the mechanical integrity to withstand tens of shots. This lifespan needs to be greatly increased if the railgun is going to be a viable next generation weapon. Hence, work is ongoing to improve the material properties and the resiliency of the barrel.

Figure 4: Railgun Prototype on Display Aboard.

Of course, increasing the resiliency of the barrel goes only so far if the heat produced from the immense amount of energy released cannot be mitigated. Accordingly, efforts are also underway to develop an efficient cooling system that incorporates active cooling channels in the barrel.

Another challenge is managing the immense gravitational forces that the projectiles will be subject to as they experience an acceleration of nearly 100,000 g’s when launched [6]. Current electronics hardening has proven to be satisfactory for railgun projectiles near the 100-nmi range, but further development will be necessary for ranges beyond 200 nmi.

Railgun Power Requirements

Accelerating a projectile to Mach 7 with only electricity is no small task. The current railgun prototype at the Naval Surface Warfare Center (NSWC) in Dahlgren, VA, is a 32-MJ system with the capability to send a projectile 110 nautical miles (nmi). Current estimations claim the railgun should be capable of firing between 6 and 12 rounds per minute [5]. The amount of power required for railgun operation can vary depending on the situation, but it usually ranges from tens to hundreds of megawatts [5]. To achieve these high energy levels, a pulsed power system has been developed to charge a bank of capacitors so they can be rapidly discharged into the gun system. This amount of power requires massive capacitor banks that add tons of weight and take up valuable shipboard space. So, for railguns to even be plausible, the power system of the respective platform will need to be designed to accommodate the weapon system.

The Integrated Ship Power Solutions

Current combatant ships allocate about 90% of engine power solely for propulsion [7]. To support the hundreds-of-megawatts power requirement of an electro-magnetic railgun and possibly other directed energy weapon systems such as high-energy lasers, more power must be allocated for weapon systems, requiring an immense power system that will consume valuable shipboard space and add a tremendous amount of weight. Such demands suggest that railguns most likely cannot be retrofitted to older Navy vessels and must instead be integrated with the development of an electrically driven warship designed for electric weapon systems.

In an integrated ship power scenario, the weapon systems would all be on the same power grid as the propulsion system. When high-speed operations are needed, most of the shipboard electric power can be directed to the propulsion system. In tactical scenarios, the engine power can be diverted to generate electricity for the weapon system.

Studies have shown that retrofitting an entire railgun system separately from the propulsion system would increase ship weight by approximately 17%. On the other hand, integrating the power systems together would only increase total ship weight by 6% [7]. When one considers that some of the new warships (such as the Zumwalt-class DDG 1000) are weighing in at more than 14,000 tons, this potential weight differential is substantial.

The Future Railgun

As previously mentioned, General Atomics and BAE Systems are both working with ONR on the development of railgun systems. By 2016, the Navy hopes to have its first test fire at sea, with a railgun mounted on a Joint High-Speed Vessel (JHSV). A primary objective of the test is to fire 20 rounds over the horizon at a stationary target. And to evaluate the system’s precision capability, five of the rounds will be GPS-guided [8].

Further, General Atomics, which envisions railguns to be a valuable weapon not only at sea but also on land, has shown interest in developing both fixed and mobile land-based railgun systems. The company’s mobile Blitzer system plans to use existing military vehicles to transport the railguns components to the desired location. The Blitzer system will also use guided projectiles to provide rapid response defense against inbound missiles and enemy launchers. Additionally, the fixed-base version of the General Atomics railgun is much more expandable and will be able to provide longer ranges than shipboard applications.

While there is growing support for continuing railgun research, significant challenges remain with regard to integrating the system into a warship. The original plan was to install railguns on future combat ships such as the DDG 1000 (Zumwalt-class) destroyer, which is an electric warship with an integrated power system. The problem is that only three DDG 1000s are planned to be built, and the first two are too far along in development to incorporate a railgun [9].

Consequently, the Navy has forgone the DDG 1000 in favor of reverting back to the DDG 51 (Arleigh Burke-class) destroyer. A potential problem with this decision is that the DDG 51 is much smaller and cannot support the railgun system unless the railgun system size decreases or the DDG 51 Flight III version larger than the Flight IIA version. Another problem is that the DDG 51 Flight III will not have an electric drive system [10]. This could significantly limit the power generation capability and may not support the power requirements of railguns or other directed energy systems in development, such as the Solid State Laser [10]. This limitation means there would have to be an additional power system on board for these weapons, adding even more weight.

Conclusions

Clearly, railguns are weapons with great potential to increase combat effectiveness, reduce logistical burdens, improve safety, and decrease operational costs. To make this potential a reality, however, a long-term, viable ship platform to support the system will be needed. Currently, there are no ship designs planned to meet this need. A railgun can be installed on the last DDG 1000, but with the Navy’s pivot back to the DDG 51 (which would require challenging modifications), that solution may only be a limited one. If the United States is to maintain its long-held technological advantage in this area, future ships will need to be designed and developed to comprehensively integrate this important weapon technology.

References:

- Hagel, Chuck. The Defense Innovation Initiative. Memorandum from the Secretary of Defense, http://www.defense.gov/pubs/OSD013411-14.pdf, 15 November 2014.

- Ellis, Roger. “Electromagnetic Railgun.” Speech at Naval Future Force Science and Technology Expo, 3 February 2015.

- Gordon, John IV, Irv Blickstein, Peter A. Wilson, Robert W. Button, James G. Kallimani, and Cobian Daniel. “The Railgun Possibilities and Challenges for Naval Surface Fire Support.”

- Ziv, Mike. “Electromagnetic Railgun.” ASNE Combat System Symposium, 26 March 2012.

- “Environmental Assessment for Construction and Operation of an Electromagnetic Railgun Research, Development, Test & Evaluation Facility.” Rep. Dahlgren: Naval Support Facility Dahlgren, 2009.

- D’Amico, William P. “Telemetry Systems and Electric Gun Projectiles.” ARL-MR-499, U.S. Army Research Laboratory, 2000.

- Clayton, David, Gary Jebsen, and John Sofia. “The All Electric Warship From Vision to Total Ship System Integration.” Tech. Dahlgren: Naval Surface Warfare Center, 2002.

- Jean, Grace. “Navy League 2015: USN Selects Fifth JHSV to Host EM Railgun At-Sea Demo.” IHS Jane’s 360, http://www.janes.com/article/50657/navy-league-2015-usn-selects-fifth-jhsv-to-host-em-railgun-at-sea-demo, 13 April 2015.

- Freedbeird, Sydney, Jr. “Hill To Navy: Hurry Up On Railguns, Lasers.” Breaking Defense. http://breakingdefense.com/2015/05/hill-to-navy-hurry-up-on-rail-guns-lasers/, 4 May 2015.

- O’Rourke, Ronald. “Navy DDG-51 and DDG-1000 Destroyer Programs: Background and Issues for Congress.” Issue brief.