Research into a new, unique technology to fabricate composite metal parts for a wide range of applications operating in extreme environments across the aviation, space, and energy industries is showing promise for additive manufacturing.

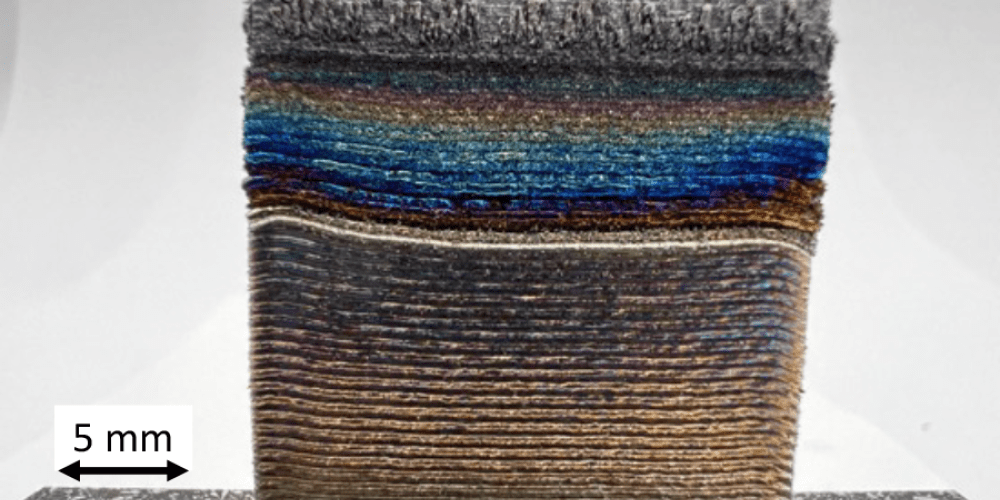

Developed by scientists at the Department of Energy’s Oak Ridge National Laboratory, this technique enables the design of compositionally graded composite parts. These components transition from high-strength superalloys to refractory alloys that can withstand extremely high temperatures — so no welding is needed. Though superalloys and refractory alloys typically cannot be welded or joined with each other, many applications require materials with site-specific high-temperature and high-strength properties.