The Navy advanced efforts to improve self-sufficiency for deployed ships and their crews and reduce supply chain lead times by leveraging additive manufacturing (AM) through the installation of the first metal 3-D printer permanently installed aboard a naval ship, November 3.

“The introduction of additive manufacturing (AM) into naval operations supports readiness and self-sufficiency,” said Rear Adm. Brendan McLane, Commander, Naval Surface Force Atlantic.

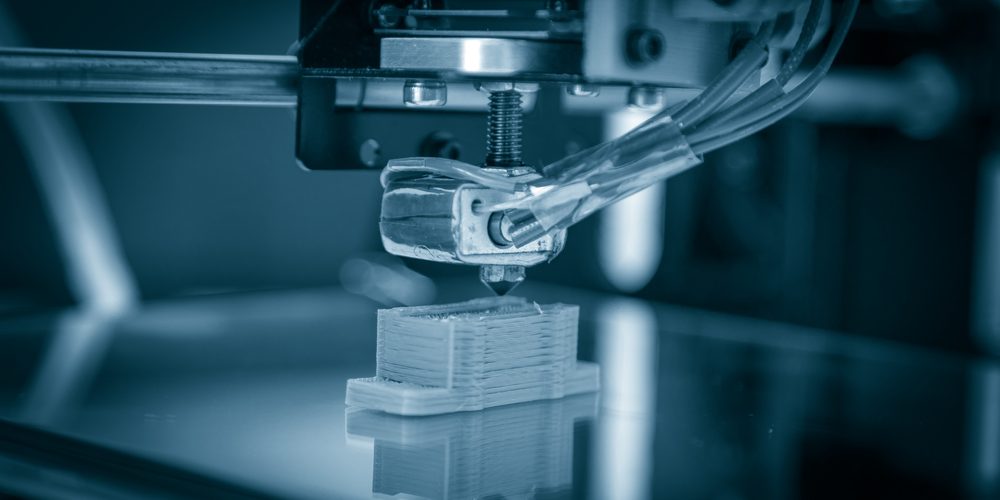

Additive manufacturing (AM) – more commonly known as 3-D printing – is the process of joining materials to make parts from 3-D model data, usually layer upon layer, as opposed to subtractive manufacturing and formative manufacturing methodologies. Whether creating a quality of life item or a sophisticated machine part, AM facilitates production at the point-of-need when time and operational availability matter.