Gallium Nitride Transistor Technology Development for HPM DEWs

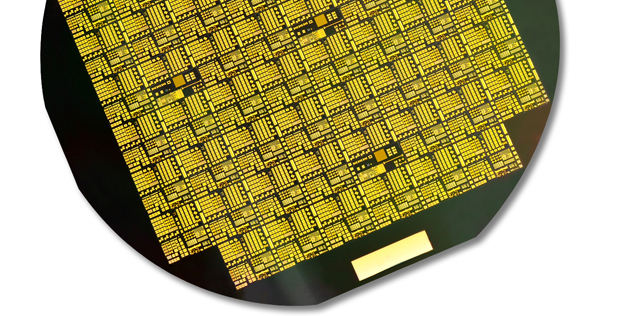

DSIAC was asked to determine the state of solid-state gallium nitride (GaN) amplifier technology development for high-powered microwave (HPM), directed energy weapons (DEWs). DSIAC used a collection of HPM DEW and microelectronics subject matter expert…