The Defense Systems Information Analysis Center (DSIAC) was asked to investigate film resistor drift and the percentage of resistance value realizable in that failure mode. A similar search for the failure modes and subsequent failure mode distributions of specific types of capacitors (CDR ceramic and CWR dry tantalum) was also requested. DSIAC used open-source information and reports in the Defense Technical Information Center Research and Engineering Gateway, as well as subject matter expert input, to respond to these inquiries. Failure modes for various resistor and capacitor types are investigated in this report, and additional, relevant resources are noted.

1.0 Film Resistors

1.1 Resistor Failure

Failure Modes and Effects Analysis (FMEA) is a systematic way to identify and evaluate the effects of different component failure modes, determine what could eliminate or reduce the chance of failure, and document the system. Failure Mode Effect and Diagnostic Analysis (FMEDA) combines FMEA with online diagnostics techniques and failure modes relevant to safety-instrumented system design [1].

1.2 Film Resistors and Drift

Resistors are passive electronic devices that impede the flow of electric current in a circuit and are used in nearly all electronics. Types of resistors include conventional ceramic, embedded, thin film, and thick film. Film resistors are single or multilayer structures manufactured by printing a layer of specially formulated paste onto a ceramic, polymeric, or metallic substrate.

Thicknesses of the paste can range from a few microns to a few millimeters. Over time, the resistive material will degrade, causing a drift in the resistance value [2]. Thin-film resistors can be made from materials including nichrome (most popular), chromium-doped silicon monoxide (SiO-Cr) cermets, tantalum, and titanium with substrates being composed of finely polished glass, glazed ceramic, and oxidized silicon. In particular, nichrome resistors can be deposited with a sheet resistance of between 1 and 300 ohms/square, with a temperature coefficient of resistance of ±50 ppm/°C, and with tolerances ±1% [3].

According to the Military Handbook (MIL-HDBK) 338B [4], film resistors consist of evaporated films of thicknesses ranging from 0.005 to 1 mm or thicker films of deposited resistive ink up to 100 mm. Table 1, from MIL-HDBK 338B, presents failure mode distributions for film resistors. In this table, “open” refers to open circuit, “parameter drift/change” refers to parameter shifts, and “short” refers to short circuit.

Table 1: Failure Mode Probabilities for Film Resistors (According to MIL-HDBK-338B) [4]

| Failure Mode | Mode Probability (α) |

| Open | 0.59 |

| Parameter Drift/Change | 0.36 |

| Short | 0.05 |

However, Naval Sea Systems Command (NAVSEA) Naval Surface Warfare Center (NSWC)-Crane states slightly different percentages (Table 2). Primary failure modes of resistors are open circuits and resistance drift, though resistors used in high-precision applications will be more prone to failure due to drift/aging effects. Film resistors are most susceptible to resistance drift [5].

Table 2: Failure Mode Probabilities for Film Resistors (According to NSWC-Crane) [5]

| Failure Mode | Mode Probability (α) |

| Open | 0.50 |

| Parameter Drift/Change | 0.45 |

| Short | 0.05 |

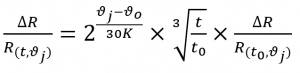

Vishay Intertechnology, Inc. published a technical note, “Drift Calculation for Thin Film Resistors” [6], which states that changes in resistance values occur with film temperature resulting from an applied electrical load and with the duration of the load. Calculations were made using the Arrhenius rate law, though modified for thin-film resistors, as shown in Equation 1.

(1)

(1)

where ΔR/R(to,ϑj) is the reference resistance drift, t is the actual time of operation, to is the reference time of operation, ϑo is the reference film temperature, and ϑj is the actual film temperature.

Using Equation 1, it was concluded that (a) the drift doubles for every 30 K increase in temperature and (b) the drift increases with the cube root of the load durations. Table 3 presents film resistor drift values for thin-film surface-mounted devices (SMDs) and leaded thin-film resistors. These values are for the standard operating maximum temperatures of these resistors (i.e., 125 °C for SMDs and 155 °C for leaded thin-film resistors).

Table 3: Film Resistor Drift [6]

|

Thin-film SMD resistor at standard operation (125 °C) |

|||

|

Load Duration |

1,000 hours |

8,000 hours |

225,000 hours |

|

Drift (ΔR/R) |

≤0.25% |

≤0.5% |

≤1.5% |

|

Leaded thin-film resistor at standard operation (155 °C) |

|||

|

Load Duration |

1,000 hours |

8,000 hours |

225,000 hours |

|

Drift (ΔR/R) |

≤0.5% |

≤1% |

≤3% |

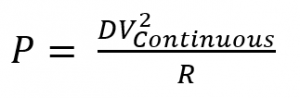

While the modified Arrhenius equation will calculate the drift in foil resistors, another Vishay technical note derives an approach to predicting the maximum drift for any requested confidence level. The prediction is based on data from long term load life testing of resistors under different conditions of ambient temperature and over shorter periods using accelerated testing of newly produced resistors. With the data and the Arrhenius equation, the drift’s standard deviation (DSD) can be calculated using the slope of a line with temperature adjustments [7].

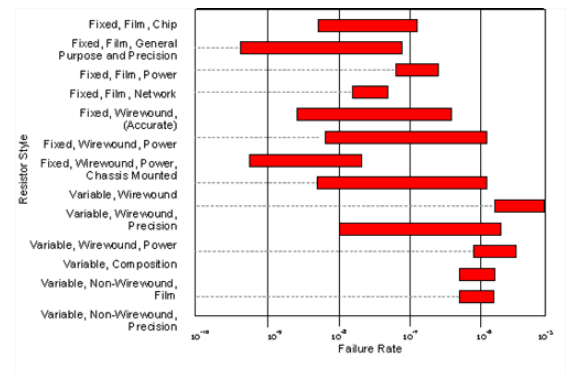

Figure 1: Relative Failure Rates for Resistors (Source: NSWC-Crane).

Resistor specifications limit full-power operation to a maximum operating temperature, Ts, and then linearly “derate” to an absolute maximum operating temperature, TMAX, at zero power. Depending on the style and failure characteristics of the resistor, applied power is derated to between 50 and 70% and then linearly derated to the zero-power point. Additional derating is specified for high voltage with high resistance value applications, such that the maximum continuous working voltage of the resistor is not exceeded. Ohm’s Law and the derating criteria can be used to determine the limit power:

(2)

(2)

where VContinuous = maximum continuous working voltage and D = derating criteria for the resistor. The derating requirements of resistors can be seen in Table 4 and more information can be found in a NAVSEA NSWC-Crane web article, “Resistors” [8].

Another paper of possible interest is “Model for Reliability Prediction of Thick Film Resistors” by R. B. Pranchov and D. S. Campbell that describes a model for time-to-failure prediction based on component parameter drift [9].

Table 4: Derating Requirements of Resistors [8]

|

Resistor Style |

Derating Parameter |

||

|

Power (Max. % Rated Electrical Stress) |

Max. Temperature (⁰C) |

Max. Voltage |

|

|

Fixed, Film, Chip |

|

|

|

|

PD < 1/2W (rated) |

70% or 70%*/R (whichever is less) |

Ts+0.70(TMAX-Ts) |

— |

|

PD ≥ 1/2W (rated) |

55% or 55%*/R (whichever is less) |

Ts+0.55(TMAX-Ts) |

— |

|

Fixed, Film (General Purpose and Precision) |

|

|

|

|

MIL-PRF-39017 Styles RL05, RL07 and MIL-PRF-55182 Styles RN50 and RN55 |

65% |

Ts+0.65(TMAX-Ts) |

70% |

|

All Others |

55% or 55%*/R (whichever is less) |

Ts+0.55(TMAX-Ts) |

70% |

|

Fixed, Film, Power |

55% |

Ts+0.55(TMAX-Ts) |

— |

|

Fixed, Film, Network |

55% or 55%*/R (whichever is less) |

Ts+0.55(TMAX-Ts) |

70% |

1.3 Subject Matter Expert (SME) Input

DSIAC searched its internal database of SMEs with related experience in resistor failure and drift and contacted two organizations found through the open-source literature search: Vishay Intertechnology and NSWC-Crane.

1.3.1 Vishay Draloric/Beyschlag Resistor Division

After finding multiple data sheets and articles published by Vishay Intertechnology, DSIAC staff contacted the company via email for further information and clarification. A product marketing engineer responded with the following information [10]:

There is a note that Vishay includes in many of the resistor series datasheets related to resistive drift:

When the resistor dissipates power, a temperature rise above the ambient temperature occurs, dependent on the thermal resistance of the assembled resistor together with the printed circuit board. The rated dissipation applies only if the permitted film temperature is not exceeded. These resistors do not feature a limited lifetime when operated within the permissible limits. However, resistance value drift increasing over operating time may result in exceeding a limit acceptable to the specific application, thereby establishing a functional lifetime.

When a resistor dissipates power (during current flow through the resistor either from a current source or voltage source) electrical energy is converted to thermal energy. The heat generated at the resistive element will cause a resistive drift over time. If more power must be dissipated by the resistor or the ambient temperature elevates, the resistive drift increases. Depending on the resistor technology (resistor size, thick film vs. thin film vs wirewound vs etc.), thermal dissipation properties of the circuit, environmental temperature of the application, et cetera; the resistive drift of a resistor will be increased or decreased.

In the Vishay datasheets there is a provided “Endurance at 70°C” maximum drift over time specification. For example, the Endurance at 70°C specification for TNPW e3 thin film chip resistor series parts for “Power operation mode” is maximum drift of ±0.1% after 1000h and maximum drift of ±0.2% after 8000h. This table also lists maximum resistive drift after 225000h (<0.6% for power operation mode). This resistive maximum drift specification represents a worst-case scenario considering full power applied to the resistor while also ensuring that maximum film temperature of +155°C is not exceeded (for power operation mode) [11]. The Law of Arrhenius can be used to predict the drift of resistors with reference drift values and resistive film temperatures (such as specified drift after 1000h as given in the Endurance test specification, and the specified maximum film temperature of component, both available in product datasheets) [6].

1.3.2 NAVSEA NSWC-Crane

After finding multiple articles related to film resistors and drifting published by NSWC-Crane, DSIAC contacted an SME liaison at that organization. It was reported that NSWC-Crane has expertise in resistors in energy storage systems and resistors in the microchip technology fields. NSWC-Crane employs multiple SMEs involved in these fields [12].

2.0 Capacitors

2.1 CWR Dry Tantalum and CDR Ceramic Capacitors

A meaningful failure analysis of a capacitor requires an understanding of its construction and materials (tantalum, ceramics, aluminum, mica/glass, film, etc.) as shown in Table 5 for tantalum and ceramic capacitors. A simple capacitor consists of a dielectric material sandwiched between two conductors with a bias applied across them. The capacitance is given by Equation 3, where ε is the dielectric constant, A is surface area, and t is thickness.

(3)

(3)

Tantalum capacitors can achieve a large capacitance in small volumes with porous tantalum anodes that are produced by pressing and sintering tantalum powder with an attached tantalum wire and an amorphous tantalum oxide dielectric electrochemically then grown on the anode. The porous anode is then impregnated with a counterelectrode manganese oxide or polymer layer.

Ceramic capacitors are constructed by alternately stacking thin layers of dielectric and electrode materials, and with alternating electrodes displaced to avoid contact between the opposing terminals [13].

Table 5: Characteristics of Tantalum and Ceramic Capacitors [13]

| Type | Dielectric | Electrode/Counterelectrode | Construction | Polar Devices |

| Tantalum | Tantalum Oxide | Tantalum/MnO2 or tantalum/conductive polymer | Porous tantalum for high surface area | Yes |

| Ceramic | BaTiO3, ZrTiO3, etc. | Base metal electrode or precious metal electrode | Layered structure for high surface area | No |

2.1.1 Failure Modes and Distributions

Failure modes for tantalum and ceramic capacitors occur either due to open circuits, short circuits, or value changes (drift); the distributions are shown in Table 6. Typically, early-life failures are caused by deficiencies in the manufacturing process, such as burred or rough foil edges, thin regions in separator paper, deficiencies in oxide films, etc., depending on the style. Failures later in a capacitor’s life are often due to excessive internal temperatures caused by high operating voltages or ripple currents. Some capacitor styles are protected against failure with a self-healing process in which a temporary short burns out a defect with minimal damage to the anode/cathode, allowing continued, albeit slightly degraded, operation. Wear-out failure mechanisms in capacitors are usually caused by the chemical effect in the dielectric and is a function of time, temperature, and voltage level. The time-temperature chemical degradation process doubles for each 10 ⁰C rise in temperature, while time-voltage degradation is more difficult to quantify because it is dependent on the dielectric type [14].

Table 6: Normalized Failure Mode Distributions for Tantalum and Ceramic Capacitors [14]

|

Capacitor Style |

Relative Failure Mode Distributions |

||

|

Open |

Short |

Value Change/Drift |

|

|

Tantalum, Chip |

32 |

57 |

11 |

|

Ceramic |

22 |

49 |

29 |

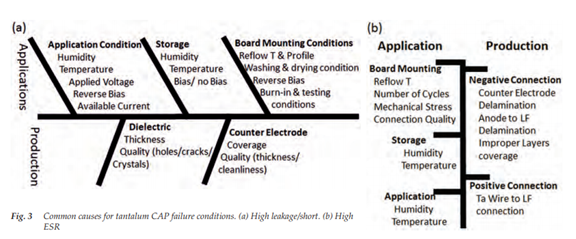

2.1.1.1 Tantalum Capacitors

There are three categories of electrical failure modes of tantalum capacitors:

- High leakage/short

- High equivalent series resistance (ESR)/drift

- Open/low capacitance.

High leakages/electrical shorts account for the most failures. Each failure mode has its own possible causes, and the most common causes for the failure of tantalum capacitors are shown in Figure 2.

Figure 2: Common Causes for Tantalum Capacitor Failure Conditions: (a) High Leakage/Short and (b) High ESR (Source: ASM International).

Short failures are caused by a conductive path between the capacitor’s positive and negative terminals, with the leakage occurring either through the tantalum anode due to a compromised dielectric or a path formed between the terminals while bypassing the anode. While physical, external damage can be nondestructively analyzed, failure can also stem from flaws, such as a crystalline oxide, that weaken the dielectric and provide a conductive path. High ESR failures are typically caused by a loose connection or an increase in the resistivity of the material. Most ESR issues for tantalum capacitors arise in the counterelectrode layers and include layer delamination, thicker-than-normal layers, a missing layer, etc. Low capacitance/open failures are the least common, though they could possibly be due to a compromised or noncontinuous positive leadframe and wire connection [13].

2.1.1.2 Ceramic Capacitors

Two factors that contribute to cracking multilayer ceramic chip capacitors (MLCCs) are the brittleness of the ceramic materials and mechanical/thermal stresses associated with the assembly process. Internal and external factors affect the susceptibility of MLCCs to cracking. Internal factors are related to material properties, internal defects, and capacitor size. External factors, meanwhile, are related to thermal and mechanical stresses caused by the soldering process and postsoldering handling of the board [15]. Ceramic capacitors commonly fail in either short or open mode due to printed circuit board flexure causing MLCC cracking. In a project performed at Sandia National Laboratories, four of seven ceramic capacitors failed from use, and three of those four shorted [16].

2.1.2 Derating

Capacitor derating is accomplished by limiting applied voltage and operating temperature [17], which ensures safe operation of the component in circuit [18]. Typically, tantalum capacitors require a two times or greater derating, while MLCCs have higher voltage strength and can withstand stress beyond their rated voltage such that derating isn’t required [18]. Table 7 provides the derating requirements of tantalum and ceramic capacitors.

Table 7: Derating Requirements of Tantalum and Ceramic Capacitors [17]

|

Resistor Style |

Derating Parameter |

||

|

Power (Max. % Rated Electrical Stress) |

Max. Temperature (⁰C) |

Reverse Voltage |

|

|

Fixed, Ceramic, General Purpose |

60 |

TMAX – 15 |

N/A |

|

Fixed, Ceramic, Temp. Comp. |

60 |

TMAX – 10 |

N/A |

|

Fixed, Ceramic, Chip (CDR) |

60 |

TMAX – 10 |

N/A |

|

Fixed, Tantalum (CWR) |

60 |

TMAX – 10 |

N/A |

|

Fixed, Electrolytic, Tantalum, Solid |

60 |

TMAX – 10 |

2% of Forward |

Other articles related to the failure modes of tantalum and ceramic capacitors are as follows:

- Tantalums

- “Failure Modes of Tantalum Capacitors Made by Different Technologies” [19].

- Vishay FIT Calculator (http://www.vishay.com/capacitors/tantalum-reliability-calculator-list/) [20]: A calculator program that enables users to predict the reliability of tantalum capacitors.

- MLCC

- “Design and Process Guidelines for Use of Ceramic Chip Capacitors” [21]: An overview of the manufacturing and potential failures of MLCCs.

- “Susceptibility to Cracking of Different Lots of CDR35 Capacitors” [22]: Exploring the effect of cracks on MLCC failure in space applications.

References

[1] Goble, W., I. van Beurden, and J. Grebe. “Failure Modes, Effects and Diagnostic Analysis.” exida.com L.L.C. http://www.emerson.com/documents/automation/fmeda-report-3051t-en-87034.pdf, 27 May 2005.

[2] Shrivastava, A., A. Amin, B. Sood, M. Azarian, M. Pecht, and M. Zagami. “Thick Film Resistor Failures.” Proceedings of the 34th International Symposium for Testing and Failure Analysis, 2008.

[3] ARINC Research Corporation. Microelectronic Device Data Handbook Volume 1: Text. NASA, https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19680020053.pdf, July 1968, Washington, DC.

[4] U.S. Department of Defense. MIL-HDBK-338B. Military Handbook: Electronic Reliability Design Handbook, 1998, http://www.navsea.navy.mil/Portals/103/Documents/NSWC_Crane/SD-18/Test%20Methods/MILHDBK338B.pdf, accessed July 2018.

[5] NAVSEA. NSWC-Crane. “Resistors Failure Mechanisms and Anomalies,” http://www.navsea.navy.mil/Portals/103/Documents/NSWC_Crane/SD-18/ResistorsFailure.pdf, accessed July 2018.

[6] Vishay Intertechnology, Inc. Technical Note. “Drift Calculation for Thin Film Resistors,” https://www.vishay.com/docs/28809/driftcalculation.pdf, 12 April 2013.

[7] Vishay Precision Group. “Predicting Drift in Foil Resistors.” http://www.vishaypg.com/docs/63171/TN104.pdf, 18 September 2012.

[8] NAVSEA. NSWC-Crane. “Resistors,” http://www.navsea.navy.mil/Portals/103/Documents/NSWC_Crane/SD-18/ResistorsDerating.pdf, accessed August 2018.

[9] Pranchov, R. B., and D. S. Campbell. “Model for Reliability Prediction of Thick Film Resistors.” Electrocomponent Science and Technology, vol. 11, pp. 185−190, https://www.hindawi.com/journals/apec/1984/391890/, 1984.

[10] Vishay Draloric/Beyschlag Resistor Division. Personal communication with product marketing engineer, August 2018.

[11] Vishay Precision Group. “High Stability Thin Film Flat Chip Resistors.” https://www.vishay.com/docs/28758/tnpw_e3.pdf, 12 May 2016.

[12] NAVSEA. NSWC-Crane. Personal communication with special operations liaison, August 2018.

[13] Qazi, J. “An Overview of Failure Analysis of Tantalum Capacitors.” In Electronic Device Failure Analysis, vol. 16, no. 2, pp. 18−23, https://www.asminternational.org/documents/10192/18102672/edfa1602p18.pdf/8f45777f-1dea-4cbd-93fb-7acb4037cdb3, 2014.

[14] NAVSEA. “Capacitors.” http://www.navsea.navy.mil/Portals/103/Documents/NSWC_Crane/SD-18/PDFs/Products/Capacitors/CapacitorsFailureRevA.pdf, 23 April 2004.

[15] Dash, S. K., P. Kumar, M. P. James, S. Kamat, K. Venkatesh, V. Venkatesh, and K. M. Bharadwaj. “Study of Cracks in Ceramic Chip Capacitors (CDR-05) of Two Different Makes.” In International Journal of Emerging Technology and Advanced Engineering, vol. 3, no. 10, https://ijetae.com/files/Volume3Issue10/IJETAE_1013_14.pdf, October 2013.

[16] O’Malley, P., D. Wang, H. Duong, A. Lai, and Z. Zelle. “Ceramic Capacitor Failures and Lessons Learned.” Sandia National Laboratories, presented at the 55th Annual NDIA Fuze Conference, Salt Lake City, UT, https://ndiastorage.blob.core.usgovcloudapi.net/ndia/2011/fuze/SessionIIIAOMalley.pdf, 25 May 2011.

[17] NAVSEA. “Capacitors.” http://www.navsea.navy.mil/Portals/103/Documents/NSWC_Crane/SD-18/CapacitorsDerating.pdf, accessed August 2018.

[18] Tse, R. “Frequently Asked Questions Regarding MLCC Voltage Strength.” TDK, https://product.tdk.com/en/contact/faq/20_mlcc_voltage_strength.pdf?disppage=1&faq_category=08, January 2009.

[19] Vasina, P., T. Zednicek, J. Sikula, and J. Pavelka. “Failure Modes of Tantalum Capacitors Made by Different Technologies.” In Microelectronics Reliability, vol. 42, no. 6, pp. 849−854, 2002. https://www.sciencedirect.com/science/article/pii/S0026271402000343.

[20] Vishay. “FIT Calculator.” http://www.vishay.com/capacitors/tantalum-reliability-calculator-list/, accessed August 2018.

[21] University of Maryland. CALCE Electronic Products and Systems Center. “Design and Process Guidelines for Use of Ceramic Chip Capacitors,” http://www.ieca-inc.com/images/Ceramic_capacitor_Failure_Mechanisms.pdf, accessed August 2018.

[22] Teverovsky, A. “Susceptibility to Cracking of Different Lots of CDR35 Capacitors.” NASA Electronic Parts and Packaging Program, https://nepp.nasa.gov/files/29210/NEPP-TR-2018-Teverovsky-CDR35-Capacitors-TN52049.pdf, 2017.

Bibliography

Fields, W., J. Reade, and D. Mahar. “Failure Mode/Mechanism Distributions 2013.” Reliability Information Analysis Center. Distribution A, DTIC Accession Number: RIAC-1992517, 31 December 2012.

National Aeronautics and Space Administration. “Military Handbook, NASA Parts Application Handbook, Volume 1 of 5, General Introduction, Capacitors, Resistors, Thermistors.” Distribution A, DTIC Accession Number: RIAC-RIAC-227759-000, 1 March 1988.

Naval Sea Systems Command, Washington, DC. “Parts Application and Reliability Information Manual for Navy Electronics Equipment.” Distribution A, DTIC Accession Number: ADA171433, 1 September 1985.