The Defense Systems Information Analysis Center (DSIAC) received a technical inquiry requesting information on the WINFIRE model related to fire burning/ignition in an environment in low-pressure/low-oxygen content environments. A subject matter expert (SME) provided information and assessed the capabilities of the current U.S. Department of Defense standard WINFIRE code, including the following:

- The Fire Prediction Model (FPM).

- The (under development) Next Generation Fire Model (NGFM) to model fire ignition and burning in low-pressure and/or low-oxygen content environments.

FPM is an engineering-level tool developed to look at ignition due to ballistic threats impacting tanks and lines in aircraft dry bays. FPM does use standard atmospheric models (e.g., Standard Day, Tropical, etc.) to describe temperatures and pressures. It also attempts to explain the effects of altitude; however, that functionality has never been validated. Additionally, the model does not allow any customizations to atmospheric composition. Even more limiting is the simplified single-step chemical kinetic model, which uses a simplified approach to minimize run time when attempting to account for incomplete combustion.

WINFIRE and the FPM were not recommended for the inquirer’s application due to the limitations identified by the SME. Although NGFM will provide improved fire ignition and modeling capabilities, it will not provide the capabilities needed to accurately model fire ignition and propagation under low-oxygen conditions.

1.0 Introduction

Defense Systems Information Analysis Center (DSIAC) staff contacted Mr. Jim Tucker, a DSIAC subject matter expert (SME), who provided a response to the inquiry.

2.0 WINFIRE Description

WINFIRE, with FPM v3.8.2 integrated, simulates events that accompany a single threat penetrating through a vehicle and impacting a container of flammable fluid (e.g., a fuel tank or pressurized line containing fuel or hydraulic fluid). Specifically, the model predicts whether ignition would occur and continues modeling events through fire growth and spread. Simulating ignition is a unique capability that distinguishes FPM from other models outside the survivability discipline, which concentrates primarily on the sustained combustion phase of fires and does not address ballistic-initiated fires. Typical visualization output is shown in Figure 1.

Figure 1: Typical FPM Simulation [1].

FPM simulates a number of generic threats to combat aircraft (including armor-piercing incendiary [API] rounds, high-explosive incendiary [HEI] rounds, and fragments), as well as other ignition sources, such as sparks and hot surfaces (e.g., from engine casing and bleed air components). In addition, the model contains temperature-dependent fluid properties for standard JP-4, JP-5, JP-8, and diesel fuels, as well as MIL-H-5606 and MIL-H-83282 hydraulic fluids. A user can enter custom fluids into FPM simulations as needed. A fire extinguishing capability is also included, and the model has an extensive library of extinguishing agents from which to choose. These features have not all been verified or validated.

FPM also models complex mechanisms that affect fire behavior, such as hydrodynamic ram (HRAM), liquid spray geometry, flow and migration, and combustion by-products. In addition to leveraging built-in data and submodels, FPM can also interface with the Projectile Penetration (ProjPen) and Fast Air Target Encounter Penetration (FATEPEN) model libraries to calculate threat-plate interactions and support ignition calculations [1].

FATEPEN is a set of fast-running algorithms that simulate the penetration of and damage to spaced target structures by compact and noncompact warhead fragments [2]. ProjPen is a threat penetration model used to predict weapon lethality and platform vulnerability to projectiles such as HEI ammunitions [3].

3.0 WINFIRE Capability to Model/Simulate Fire in Low-Pressure and/or Low-Oxygen Content Environments

WINFIRE’s capabilities, and more specifically the capabilities of the FPM core regarding combustion calculations, would not be suited for the inquirer’s problem. FPM is an engineering-level tool developed to consider ignition from ballistic threats impacting tanks and lines in aircraft dry bays. As such, it does attempt to consider the effects of altitude, but that functionality has never been validated.

FPM uses standard atmospheric models (e.g., Standard Day, Tropical, etc.) to describe the temperatures and pressures. The model does not allow any customizations to atmospheric composition. More limiting is the simplified single-step chemical kinetic model used. FPM attempts to account for incomplete combustion, but there are many simplifications done to minimize run time. A new tool, the NGFM, is currently under development and will provide improved ignition prediction capabilities, but this will not bring the NGFM tool any closer to aligning with the inquirer’s interests.

The article “Next Generation Fire Modeling” discusses the evolution of FPM and NGFM and provides details on development and expected capabilities of NGFM [4]. FPM is a Joint Aircraft Survivability Program (JASP) software tool developed organically over many years, beginning in the 1990s, to support fire simulation in aircraft and ground vehicles. The model uses a combination of empirical relationships and basic physics, heat transfer, and chemistry to predict the chain of events beginning with penetration through HRAM, fuel spray, droplet vaporization, and chemical reaction to predict ignition probability. In addition, FPM simulates events beyond ignition, including sustained combustion, thermal transfer to internal components, fire extinguishing, and ullage deflagration [4].

WINFIRE was created to serve as a user-friendly graphical user interface for FPM. Although FPM was conceived and designed to touch each portion of the fire chain, there are many parts of the model that are approximated or estimated simply due to a lack of developed physics and a lack of empirical data. As such, the new tool in development (i.e., the NGFM) will address these issues [4].

Knowledge gained in recent years from test programs has improved data diagnostic information, resulting in a better understanding of the detailed aspects for threat characterization, fluid spray, and ultimately, ignition. As a result, enhanced fire prediction and modeling capabilities beyond those currently available in FPM could now be developed to help address the increasing cost of testing and test assets and support the growing challenges of integrating optimized vulnerability reduction technologies into aircraft. As a result, JASP sponsored project M-14-11 to develop NGFM [4].

The following is an excerpt from the article “Next Generation Fire Modeling” [4]:

From the beginning, the ultimate goal of NGFM was to provide the analysis and test community with a model that is:

-

Fast-Running: The model will support higher level vulnerability analysis codes, which need to run as many as tens of thousands of scenarios for a single threat at a single velocity. Therefore, NGFM must be capable of running in the sub-millisecond timeframe (i.e., faster than real time).

-

Credible and Validated: A key reason for the lack of confidence in current tools is the lack of validation. To avoid this problem, NGFM must be validated at the most basic level as part of the development process.

-

Modular: Modular development has many benefits, including supporting validation, allowing for parallel development efforts, and aiding in incremental development, where improved modules can easily replace less-effective versions.

The first version of NGFM (supporting ignition due to API projectiles and warhead fragments, but not self-sustained combustion) will be available in fiscal year (FY) 2020.

4.0 KIVA Models

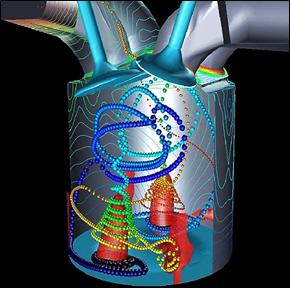

One other U.S. Government model (i.e., family of models) might provide some of the desired capabilities—the KIVA family of computational fluid dynamics models developed by Los Alamos National Laboratory, NM. These models predict complex fuel and air flows, as well as ignition, combustion, and pollutant-formation processes in engines. The models have been used to help understand combustion chemistry processes, such as auto-ignition of fuels. Typical KIVA visualization output is shown in Figure 2. As these models focus on internal combustion engines, they may not be flexible enough to support the inquirer’s desired uses [5].

Figure 2: Typical KIVA Simulation [5].

References

[1] Defense Systems Information Analysis Center (DSIAC). “WINFIRE.” https://www.dsiac.org/resources/ models_and_tools/winfire, accessed February 2019.

[2] DSIAC. “Vulnerability Toolkit.” https://www.dsiac.org/resources/models_and_tools/ vulnerability-toolkit, 12 February 2019.

[3] Office of the Secretary of Defense, Deputy Operational Test & Evaluation. “Live Fire Test and Evaluation.” In FY18 LFT&E Program, https://www.dote.osd.mil/pub/reports/FY2018/pdf/ other/2018lfte.pdf, pp. 221–228, accessed 27 March 2019.

[4] Tucker, J. “Next Generation Fire Modeling.” Aircraft Survivability, http://jasp-online.org/asjournal/spring-2017/next-generation-fire-modeling/, Spring 2017.

[5] Richard P. Feynman Center for Innovation. “KIVA.” Los Alamos National Laboratory, NM, https://www.lanl.gov/projects/feynman-center/deploying-innovation/intellectual-property/software-tools/kiva/index.php, accessed 27 March 2019.