The use of polymer additive manufacturing (AM) for single-use and reusable medical devices in austere environments is of interest to the U.S. Department of Defense. The ability to field a deployable AM resource with enough filament to sustain 60–90 days helps create a more independent and well-rounded medical team and closes air gaps on supply chain reliance. This report includes a literature survey to gather insights into the available medical sterilization technologies and align them with the properties of AM polymers and their susceptibility to degradation. Suitability is assessed using a material compatibility matrix, evaluating each method while considering parameters such as glass transition temperature and reactivity. Only thermoplastic polymers used in fused deposition modeling (FDM) printing were considered; geometric challenges were not evaluated. Ethylene oxide and hydrogen peroxide gas plasma sterilization methods were found to be most effective for FDM materials. Conversely, the autoclave and dry-heat methods commonly used for surgical instruments performed poorly. The findings offer stakeholders an early framework for decision-making, enhanced patient safety, and the progressive advancement of AM within the realm of medical applications.

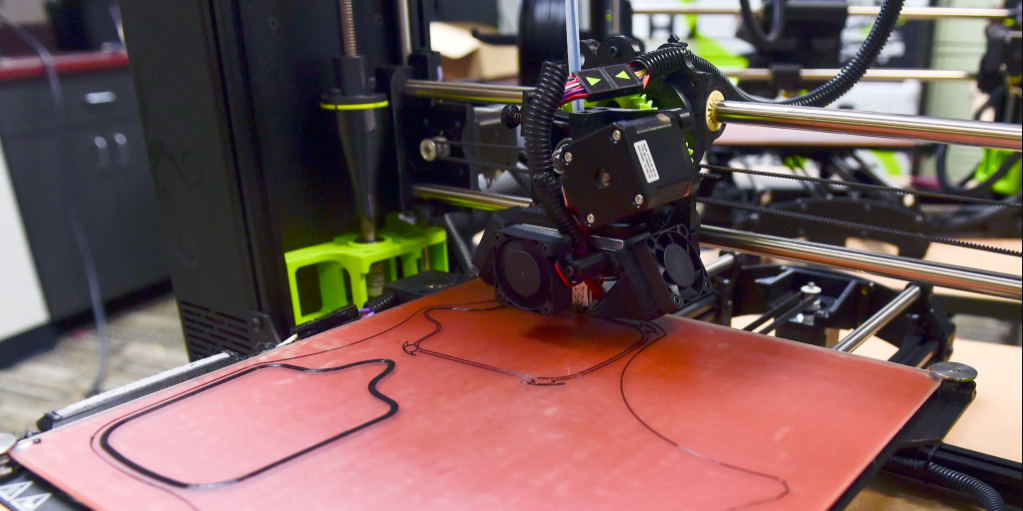

Sterilization Techniques for 3-D-Printed Materials and Medical Items

Photo by Navy Petty Officer 2nd Class Michael Lopez

Posted on September 19, 2023 | Completed on May 16, 2024 | By: Travis J. Kneen

What AM materials can be medically used and reused under military central sterile processing standards?

Want to find out more about this topic?

Request a FREE Technical Inquiry!